Vice Head of Tokyo Tech GXI, Prof. Yoshinao KOBAYASHI

Vice Head of Tokyo Tech GXI, Prof. Yoshinao KOBAYASHI

Tokyo Tech GXI promotes innovative approaches in the steelmaking industry as an important part of our efforts to build a sustainable future. Steelmaking has a significant environmental impact due to its large amount of carbon dioxide ( CO2 ) emissions, and is considered one of the causes of global warming. The ironmaking process uses carbon sources such as coal and coke to reduce iron ore, which emits large amounts of CO2. 1 ton of iron involves about 2 tons of CO2 emissions. As such, it accounts for about 14% of Japan's total CO2 emissions, making carbon dioxide reduction in the iron and steel industry an urgent issue. To address this challenge, GXI is working to redesign the steelmaking process and develop technologies to reuse carbon dioxide.

Reducing carbon dioxide emissions from steelmaking processes is also important from a carbon cycle perspective: the release of CO2 into the atmosphere not only contributes to global warming, but also affects the global carbon cycle. CO2 on Earth interacts with carbon sinks such as plants and oceans to facilitate the carbon cycle. However, large CO2 emissions from the steelmaking process disrupt this cycle and increase the burden on the global environment. Therefore, it is important to reduce CO2 emissions in consideration of the carbon cycle.

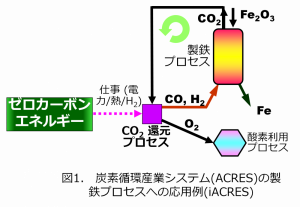

GXI The core of the ironmaking process proposed by MCC is an ironmaking system based on the Active Carbon Recycling Energy System (iACRES) (Figure 1). This system employs a process that utilizes carbon monoxide (CO) and hydrogen ( H2 ) to obtain iron, thereby significantly reducing CO2 emissions that are unavoidable in the conventional ironmaking process. Specifically, iron is obtained by reducing solid iron ore or slag containing molten iron oxide with CO or H2. Furthermore, the carbon dioxide and water produced as by-products in this process can be reused by converting them back to CO and H2 using zero-carbon energy sources such as renewable energy and nuclear energy, thereby realizing carbon-neutral ironmaking.

This innovative approach is key to moving the steel industry in a sustainable direction. By achieving a carbon cycle in the steelmaking process and significantly reducing CO2 emissions, we aim to realize a sustainable steelmaking industry. In addition to the steelmaking process, GXI is also working to reduce the environmental impact of various industrial sectors. If these efforts are successful, they are expected to significantly reduce the burden on the global environment and contribute to the realization of a sustainable society.

GXIs efforts go beyond the development of sustainable technologies in the steel industry, and its results can spread to other industrial sectors. by providing solutions to issues such as global warming and environmental pollution, GXI is playing an important role in helping to realize a sustainable society. we are confident that the GXI initiative will continue to make further progress and produce innovative technologies and methods that contribute to the global environment.