Research Outline

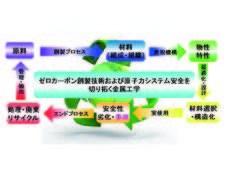

Zero Carbon Material Technology through the Creation of Material Circulation Systems

In order to create a zero-carbon society, it is essential to devise manufacturing processes in a carbon-neutral loop for structural and functional materials creation technology. Steel is the base material for construction, transportation, and energy generation, and we will lead the way in creating a material-circulating society by realizing zero-carbon steelmaking through the use of recycled steel and zero-carbon energy, replacing conventional manufacturing processes that inevitably emit CO2 from iron ore and coal.

Research on Improvement of Material Reliability for Next-Generation Innovative Reactors

We are conducting research on highly reliable and sound metallic materials that are necessary for the safe long-term operation of nuclear power systems. In order to improve the integrity of metallic materials such as nuclear fuel cladding, pressure vessels, and steam pipes, which are used for a long time under high temperature, high corrosive stress, and irradiation, we are developing and characterizing processes to optimally control composition and microstructure.

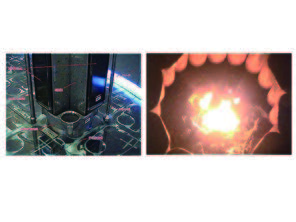

Study on Accessibility of Fuel Debris Extraction after Severe Accident in Boiling Water Reactor

In order to evaluate the accessibility of fuel debris removal for accelerating decommissioning after severe accidents, we are evaluating material damage caused by the reaction between fuel debris and core substructure. In addition, thermodynamic properties of the system consisting of fuel, control rods, and structural materials are being investigated to estimate in-core conditions by product behavior and to evaluate the phase stability necessary for safe fuel debris removal and storage.

Fig. 1 Conceptual diagram of zero carbon creation technology and metallurgy for nuclear system safety

Figure 2 Creation of thin sheets by strip casting from scrap iron

Fig. 3 Reactor core structure and simulated fuel system debris melting test using cold crucible