Laboratory for Zero-Carbon Energy, Institute of Innovative Research, Tokyo Institute of Technology

Laboratory for Zero-Carbon Energy, Institute of Innovative Research, Tokyo Institute of Technology

Director/ Prof. Yukitaka Kato

In her inaugural speech in May 2023, MIT's new president, Prof. Sally Kornbluth, cited climate change and nuclear fusion as themes that MIT needs to address urgently. Kornbluth went on to point out that each theme is a complex subject that is difficult to solve individually, and that collaboration among different minfields is important. Although this is only an assertion by one university, I felt that it perfectly expressed the current global trend. In Japan, industry, government, and academia are working together to achieve Carbon Neutrality (CN) by 2050 as a measure against climate change.

Tokyo Tech GXI started the Green Transformation Initiative in fiscal year 2022, which considers technological innovation to realize CN (carbon neutral) as GX. The Tokyo Institute of Technology has launched the GXI in fiscal 2022. The Tokyo Institute of Technology has launched GXI project in FY2022.

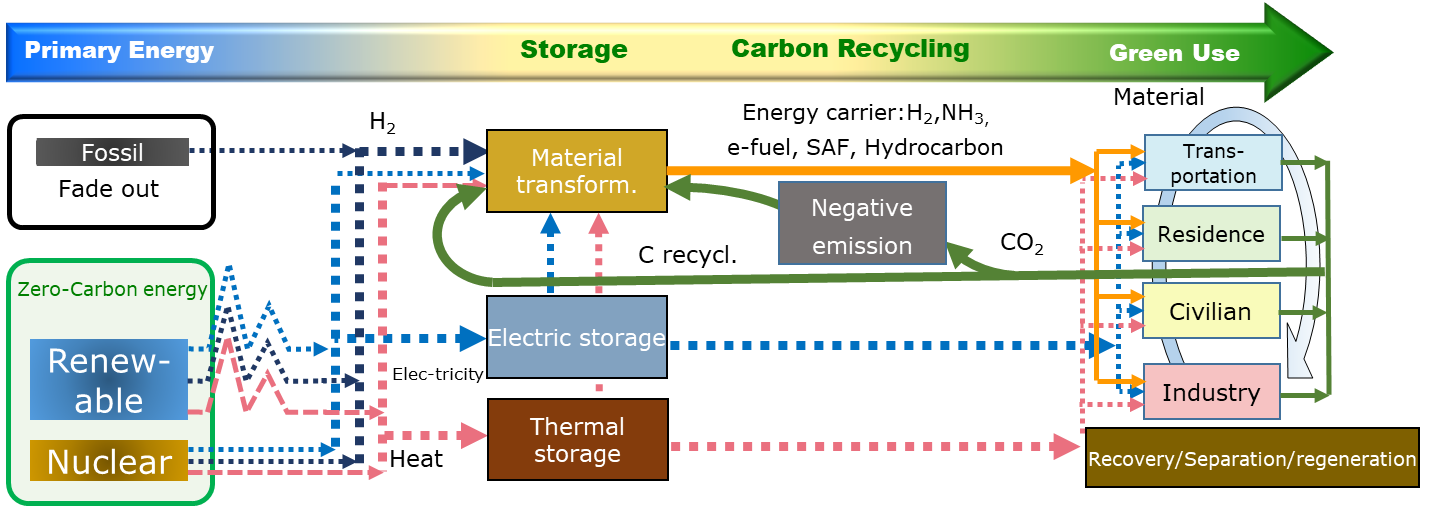

The goal of CN (carbon neutrality) is defined as a green society, and the vision of the green society that Tokyo Tech GXIis aiming for is shown in the Figure1). GX technology is the technology that will enable the achievement of this society. The necessary GX technology fields can be divided into three areas: (1) zero-carbon energy, (2) energy storage and conversion, and (3) carbon recycling and negative emissions.

Figure 1) Green Society Vision of Tokyo Tech GXI1) Overview of ZC, Tokyo Tech, http://www.zc.iir.titech.ac.jp/jp/events/publications/files/Overview_ZC_2023.pdf

Figure 1) Green Society Vision of Tokyo Tech GXI1) Overview of ZC, Tokyo Tech, http://www.zc.iir.titech.ac.jp/jp/events/publications/files/Overview_ZC_2023.pdf

Non-fossil primary energy is important, and renewable energy and, globally, nuclear energy are options. The challenge for renewable energy is non-steady-state output. Currently, the power grid cannot handle excessive electricity output, so output control is in place to plan output shutdowns in advance. Kyushu Electric Power is implementing output control for more than 80 days or 4% of total electricity output in FY2021. In FY2023, output control will be expanded to all power companies except TEPCO. Even if renewable energy generation is increased in the future, the amount of electricity that can be used within the power network will be limited, which will hinder the spread of renewable energy use, so it will be necessary to overcome the controls.

On the other hand, electricity prices have been raised significantly this year. This is due to the sharp rise in fossil fuel prices triggered by the Ukraine crisis. However, Kyushu Electric Power plans to raise its prices considerably less than other companies. This is because nuclear power generation accounts for a larger proportion of its electricity generation than other electric power companies, and the burden on fossil fuels is smaller. Judgments regarding nuclear power generation must be made in consideration of electricity and energy costs. The United States, the European Union, and China are proceeding with the planning and construction of small and large reactors one after another, and it is necessary to closely monitor why progress is being made.

Energy storage and conversion are essential for expanding the introduction of renewable energy and overcoming output constraints. The power storage represented by lithium-ion batteries must continue to be developed from the kWh order for electric vehicles to the MWh order for the power grid. However, materials such as lithium, cobalt, and nickel are unevenly distributed among producing countries, and it is important to develop alternative materials and to recycle and reuse materials. Thermal storage is also an alternative candidate for low-cost, high-volume storage. The enthalpy-based heat demand accounts for 70% of Japan's final energy consumption (estimated at 300 GW), and heat storage and utilization at various temperatures is quantitatively important to achieve CN (carbon neutrality), and new heat storage materials and systems are required.

Material conversion utilizing zero-carbon energy is also important. Green hydrogen production through water electrolysis is fundamental. Hydrogen is an environmentally friendly energy carrier, but its energy density per volume is low, and pressurization and liquefaction require a considerable amount of energy, making storage and transportation very costly. Therefore, ammonia, which is relatively easy to transport, is being considered as a hydrogen carrier. In addition, e-fuel, a hydrocarbon fuel synthesized from carbon dioxide ( CO2 ) emissions and green hydrogen, and SAF are attracting attention as environmentally friendly synthetic fuels. On the other hand, there are fields where energy cannot be replaced by electricity, heat, or hydrogen. For example, diesel engines are durable and must continue to be used in mobile vehicles that require high power output for long periods of time, and the European Union has decided to electrify all mobile vehicles by 2035, but has switched to allowing only e-fuel to be used in engines this year. However, burning e-fuel generates CO2 secondarily, and only 50% of CN can be achieved. CCR ( CO2 Capture and Recycling) is expected to be necessary to recover CO2 and recycle it into e-fuel.

The steelmaking sector is one of the sectors that emit large amounts of CO2, and green steel production without CO2 emissions through direct hydrogen reduction ironmaking is making progress. SSAB of Sweden has realized hydrogen reduction ironmaking under the HYBRID brand and will begin green steel production in 2021. Hydrogen was previously thought to be expensive and difficult to use in comparison to coal, but HYBRID is being realized using water electrolysis hydrogen from Sweden's abundant hydroelectric power generation. The cost of making pig iron is said to be about 1.3 times that of conventional pig iron, taking carbon pricing into account. Even though green steel is expensive, Mercedes-Benz and Volvo are purchasing it. Demand is expected to grow as a material for CO2-free green cars under the Scope 3 standard, which traces CO2 generation back to raw material production SSAB has had a manufacturing plant in operation just five years since 2016, when it conceived of hydrogen steelmaking. In Sweden, H2 Green Steel further plans to build a 5 million ton/year hydrogen ironmaking plant in 2030, which will exceed the capacity of large blast furnaces.

The world is undergoing a discontinuous game changing of industries to become CN (Carbon Neutral). Tokyo Tech GXI has organized an industry-government-academia collaboration committee (Industry-Government-Academia Collaboration Committee) to study the creation of GX technology. Tokyo Tech GXI aims to create GX technologies that are truly necessary to realize the vision shown in Figure 1.

Especially in Japan, technological collaboration in the field of industrial technology is more advanced than ever before. We hope that this culture of good collaboration will lead the world in the advancement of GX technology.