Laboratory for Zero-Carbon Energy, Tokyo Institute of Technology

Laboratory for Zero-Carbon Energy, Tokyo Institute of Technology

Assistant Prof. Shintaro Yasui

Highly efficient use of energy is an important issue in promoting carbon neutrality. Various options for energy storage are necessary depending on the amount of energy to be stored, but the most familiar energy storage in our daily lives is probably the battery. Recently, lithium-ion rechargeable batteries have become indispensable for energy storage in our daily lives, and from the viewpoint of safer use, all-solid-state batteries are being promoted. Liquid lithium-ion batteries containing organic solvents, which are currently in use, have excellent manufacturing cost performance because optimization including the manufacturing process has been fully minstudied. A familiar example is the tremendous price decline of mobile batteries per unit capacity in the last decade. If we disregard the "burnability" of batteries, there is a controversy about the necessity of making batteries all-solid-state. Therefore, absolute merits are required for the practical application of all-solid-state batteries in place of existing liquid batteries. For example, if the high energy density, high output, and high cycle performance required for electric vehicles (EVs) can be achieved, this should be a turning point for the shift to all-solid-state batteries. On the other hand, it is also true that high cost is a disadvantage.

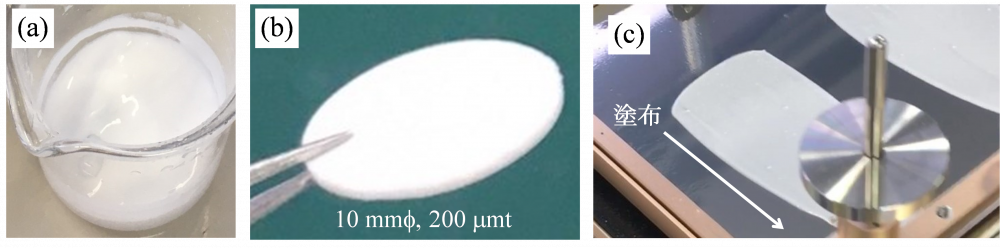

Sulfide-based All Solid-State Batteries, which are the closest to commercialization at this time, are known to be very susceptible to water min(it should be added that liquid-based lithium-ion batteries are also susceptible to water min). At the very least, processing in a dry room with a dew point below -60°C is required, which prevents lower costs. The material cost of the solid electrolyte is also not cheap. To overcome these disadvantages, we propose an all-solid-state battery that can be handled in air and does not require strict dew point control, developed from a completely different perspective from conventional battery fabrication 1). The process is based on a water-based slurry and expanded to a coating technique used in conventional liquid systems. The base materials of the solid electrolyte are ceramics 2), lithium salt, and water. The free water used in the process must eventually be removed because the presence of freely moving water (free water) during battery operation causes operation failure due to the electrical mindissolution of water. A battery with free water removed will operate at least 1,000 times or more if the conditions are chosen. The battery drive voltage is relatively small at 2.35V (about 2/3 of the voltage of liquid batteries), but the potential to bring the manufacturing cost down to a level comparable to liquid batteries may be a winning point.

References

1) A Game Changer for All-Solid-State Batteries: New Solid Electrolytes by Facing the Hated Water - Applied Physics, Nov. 2023.

2) Sosuke Takei, Ayumi Itoh, Yoshinao Kobayashi, Keigo Kamata, and Shintaro Yasui, Jpn.