Research Outline

Fabrication and Application of DLC (Diamond-Like Carbon)

DLC has excellent properties such as high hardness, low coefficient of friction, and chemical stability with diamond-like properties. We promote further functionalization of DLC coatings, which have been applied to coatings with a high coefficient of friction and wear resistance. Specifically

(1) Development of a deposition method for high wear-resistant textured DLC films and B-C-N adamant films, and evaluation of their mechanical and tribological properties. (2) Design surfaces that protect mechanical parts even under severe conditions where foreign matter such as sand is mixed in the lubricating oil. (3) We improve the chemical resistance and biocompatibility of DLC by adding tertiary elements to C and H, which constitute DLC, to develop medical devices with high biocompatibility. (4) Develop DLC-based coatings that can release any resin or adhesive.

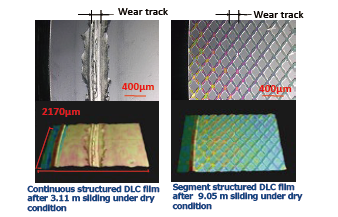

FIGURE 1 PROPOSED MICRO SURFACE STRUCTURE (SEGMENTED STRUCTURE) DLC FILM

The segmented structure is clearly observed in the micron-order fine surface structure film on the right, compared to the continuous structure film on the left.

The effect of segmental structuring is also evident in the ball-on-disk test under dry conditions. The left continuously structured film is completely peeled off and worn away after 3.11m, whereas the segmented structure shows no wear even after 9.05m of sliding, making it difficult to locate the sliding area.